Case Study: Tankers

Enhancing Delivery Efficiency and Reducing Waste for an International FMCG Company

Client Overview:A leading international Fast-Moving Consumer Goods (FMCG) company approached Strategic Innovation (SI) with the challenge of minimising wastage of a highly viscous substance during road transportation. The objective was to propose practical approaches to maximise transfer efficiency. |

|

|

Background:Waste management and resource optimization are critical concerns for all businesses, especially in industries dealing with substantial volumes of materials. In this case, the FMCG company was grappling with the issue of residual material being left within transportation tankers after delivery. This challenge prompted the company to seek out SI’s expertise in strategic innovation and problem-solving to identify the root causes of the issue and develop effective solutions. |

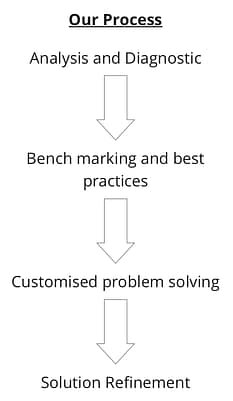

Our Approach:Strategic Innovation was tasked with comprehensively investigating the problem and devising strategies to enhance the efficiency of the delivery system. The engagement involved several key steps:

|

|

|

Outcome:

|

- October 20, 2023

At Strategic Innovation (SI), we stand at the forefront of creative problem-solving and strategic innovation. When approached by a prominent international Fast-Moving Consumer Goods (FMCG) company, we embraced the challenge of minimising material wastage in their transportation tankers with zeal. Our analytical prowess, combined with the power of TRIZ-based solutions, allowed us to guide our client towards heightened operational efficiency, reduced waste, and a more sustainable future. With a proven track record spanning various industries, we were the natural choice for a transformative partnership that exemplifies our commitment to delivering tangible results for businesses and the environment.